Home • Manufacturing Process • Ring Rolling

Ring Rolling

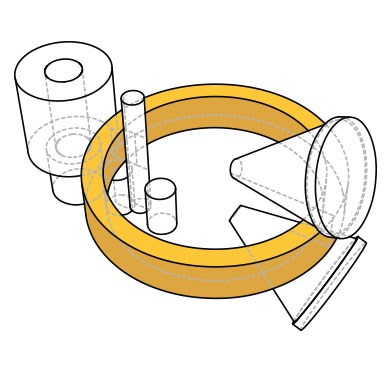

Another effective and specific metal forming process is ring rolling, a hot forming process that produces seamless rings.

The metal is rolled between two rolls, which move toward each other to form a continuously reducing gap.

The process begins with a hollow circular preform that has been upset and pierced using hydraulic press. Then, the preform is placed over the idler or mandrel roll, which is forced toward the drive roll. The drive roll rotates continuously, reducing the wall thickness and increasing the diameter.

For larger rings, the mill also have radial oriented or "pinch" rolls, which control the height of the ring. They also help to maintain “squareness” and alignment with virtually no axial growth. In some cases, such rolls can reduce the height as much as required. Ring rolling produces seamless rings with forged properties, which results in optimum mechanical properties, and predictable and efficient machinability.

s

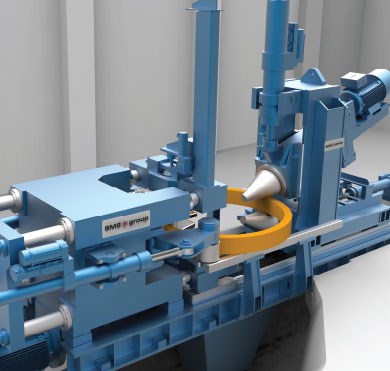

The New SMS Ring Roller

Forgia Rapida has recently installed a brand new SMS ring roller.

The Ecompact@ ring rolling machine type RAW 100/80 features electro-hydraulic direct drives that are mounted on the roll shafts, which represents an innovative drive solution for this type of application. In this machine, the otherwise common central hydraulic system has been eliminated.

Consequently, no associated machine and foundation pipework needs to be installed. This not only provides economic benefits, but also reduces energy consumption and eliminates the risk of environmental pollution by oil leakage.

Thanks to this new investment, Forgia Rapida can expand its product range, offering small/medium series of rings, in several steel grades and size, from 300 to 2.700 mm in outer diameter, from 40 to 450 mm in height and up to 3.000 kg in weight.